HOTELS

HOTELS

Sewage Treatment Plants For hotels

Sewage, commonly referred to as wastewater, is a substance that originates from buildings such as houses, schools, businesses, and factories as well as groundwater, surface water, and storm water. Nowadays, a lot of hotels are not linked to the main sewerage system, therefore building a sewage treatment facility for your hotel is essential.

Because before sewage or wastewater is discharged into the environment or utilised again, a sewage treatment facility, also referred as a wastewater treatment plant or a water pollution control plant, can eliminate the bulk of toxins from it in just a few hours. Sewage or wastewater from hotels undergoes a few treatment stages to eliminate the bulk of mineral and organic contaminants before it is clean enough to be safely discharged into wetlands.

The main objective of a hotel’s STP is to disinfect the wastewater influent to prevent the spread of disease to people. Hotel trash is gathered and delivered to the treatment facility, where it is processed utilising drains and collectors over the course of several phases. Small, compact, and efficient sewage treatment facilities for small, medium, and big hotels and resorts use mechanical, chemical, and biological treatments and techniques to lessen pollution (i.e. water pollution).

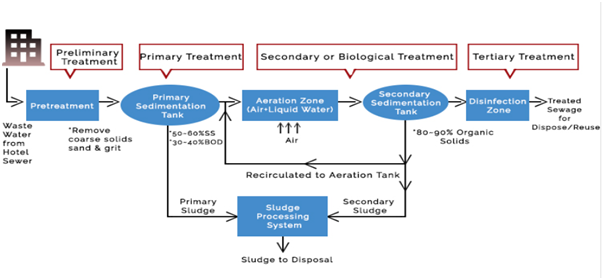

The following is a flow chart of the traditional treatment method for STP (in hotels):

The initial stages of treatment in a hotel sewage treatment plant are as follows:

Preliminary treatment, sometimes referred to as mechanical or physical treatment, is the first stage in the process of treating waste water and must be finished before primary treatment. During this phase, solids are eliminated using screening, sedimentation, and skimming. To screen coarse debris out of the system is its principal objective. Mechanical screens with bars that remove rags, twigs, papers, beverage cans, and other similar things filter incoming wastewater, also known as influent.

Sand and grit are removed using a grit chamber. Quite a bit of oil and grease are also removed by this procedure. It’s essential for preventing the pumps and other treatment process equipment from breaking down.

2-Primary Treatment: Prior to biological treatment, which is referred to as secondary treatment, this is also known as physical-chemical treatment. Using sedimentation and flotation techniques, it seeks to remove both organic and inorganic particles. Primary clarifiers or sedimentation tanks are used to allow water that has undergone preliminary treatment to pass through. In order to encourage sedimentation, the flow of wastewater is reduced during this process. This causes a considerable fraction of the floating debris, such as grease and oil, to rise to the surface and be skimmed off. The settled material will then go through the sludge digestion process, which is known as primary sludge. This process removes around 50–60% of the suspended particles in the influent and reduces BOD levels by 30-40%. The cleared water proceeds to the next treatment process.

3-Secondary Treatment: This biological treatment technique uses the “Activated Sludge Process," one of the biological aerobic processes, to break down organic contaminants. During this process, primary effluent is piped into aeration tanks where it is combined with microorganisms. The development of bacteria will quicken in aeration tanks when air is added, enabling the breakdown of organic material still present in the effluent. A secondary clarifier is where bigger particles and other solids settle to form secondary sludge after being added to aerated wastewater.

In order to encourage the activated sludge process and get rid of as many impurities as possible, some sludge will be returned to the aeration tank. The primary sludge and residual sludge are blended in the sludge processing system for further processing after being removed from the tank. At this point, between 80 and 90 percent of the organic solids have been eliminated. The water moves on to the next step after completing this one.

4. Tertiary Treatment: A small sewage treatment facility’s final stage involves using physical, chemical, or biological techniques to get rid of any remaining suspended particles or dissolved materials. Disinfection is required because processed wastewater may still contain pathogenic bacteria even after primary and secondary treatment. The process of disinfection involves eradicating dangerous germs from effluent using chemicals like chlorine, ozone, UV light, or other disinfectants. Instead of chlorination, which releases residual chlorine into the environment, the use of ozone and ultraviolet disinfection results in cleaner effluent. Because it safeguards human health, the tertiary treatment, sometimes referred to as disinfection therapy, is a crucial step in the healing process.

The hotel industry gets very busy around the holidays. Sewage production is substantial, and it must be treated before being released into the environment. Hotels, resorts, etc. must have a STP plant.